Recyling Plastic: Part 3

|

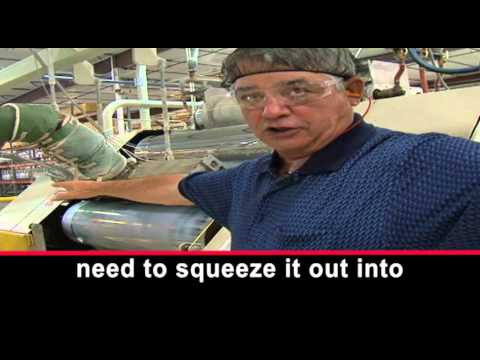

This is Peninsula Packaging -- a recycling business in the city of Wilson, North Carolina. Mark Rath works for the company. MARK RATH: "This is how it comes to us and then we reprocess it into another product." It is here that pieces of plastic become new products. MARK RATH: "Become a plastic sheet, and eventually a thermoform product." Peninsula Packaging melts and flattens plastic so that it can be shaped. MARK RATH: "We take the clear chips like this, and it goes into an oven, and it cooks for about three to four hours." Now, it can be molded. MARK RATH: "In order to do that you need to squeeze it out into a wide, long sheet." The plastic is then wrapped, rolled and sent to what is called a "thermoform station." MARK RATH: "Well, we unwind the plastic into a very long oven where we heat it -- again -- and then we'll form it in a forming station. We'll follow it through and see what happens to it." MARK RATH: "That'll end up being a fresh-cut-salad base. Not sure where it goes, but it'll end up some place with celery and carrots and tomatoes." In just a few days, a plastic bottle purchased in Washington, DC has become a salad container in North Carolina. I'm Mario Ritter.

|